TYPE T

PVC-Cold-Welding Paste

Field of application

Seam sealing of PVC-floor coverings with textile backing

and closely-cut seam (new installation with double cut)

Characteristic

- T-nozzle (T-shaped attachment for the nozzle)

Properties

- levelling of height differences of seam edges while welding

- optimal seam guidance

- T-shape of the nozzle and consistency of the paste prevent absorption of the

cold-welding product by the textile backing

Process

Same procedure as for TYPE A, the T-nozzle takes the position of the needle.

Durability

The durability lasts 3 years from the date of manufacturing, if the product is always kept dry, free of frost and not stored above 30 °C.

Delivery programme

Available in sales boxes (displays) with tubes 44 g.

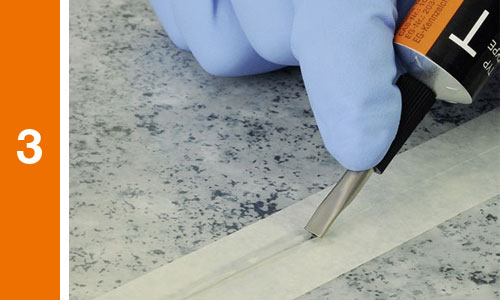

3 steps to a successful seam sealing exemplified by TYPE T

Cut the masking tape in the seam area with a rolling knife, a trapezoid blade or a hook blade.

In case of stiff or little flexible PVC-floor coverings (for instance Commercial Floor Coverings) warm up the seam area to a maximum of 40 °C by using a blow dryer or an iron before welding.

Precautionary we recommend the use of safety gloves approved for Tetrahydrofuran for the prevention of skin contact (splash protection).

Always work with both hands!

Hold the tube in such a way that the index finger of one hand guides the cannula and the other hand holds the tube.

With one hand press the screwed T-nozzle deeply into the seam and pull along. With the other hand control the rinse of the cold-welding paste so that an approx. 5 mm wide moistening appears on top of the masking tape.