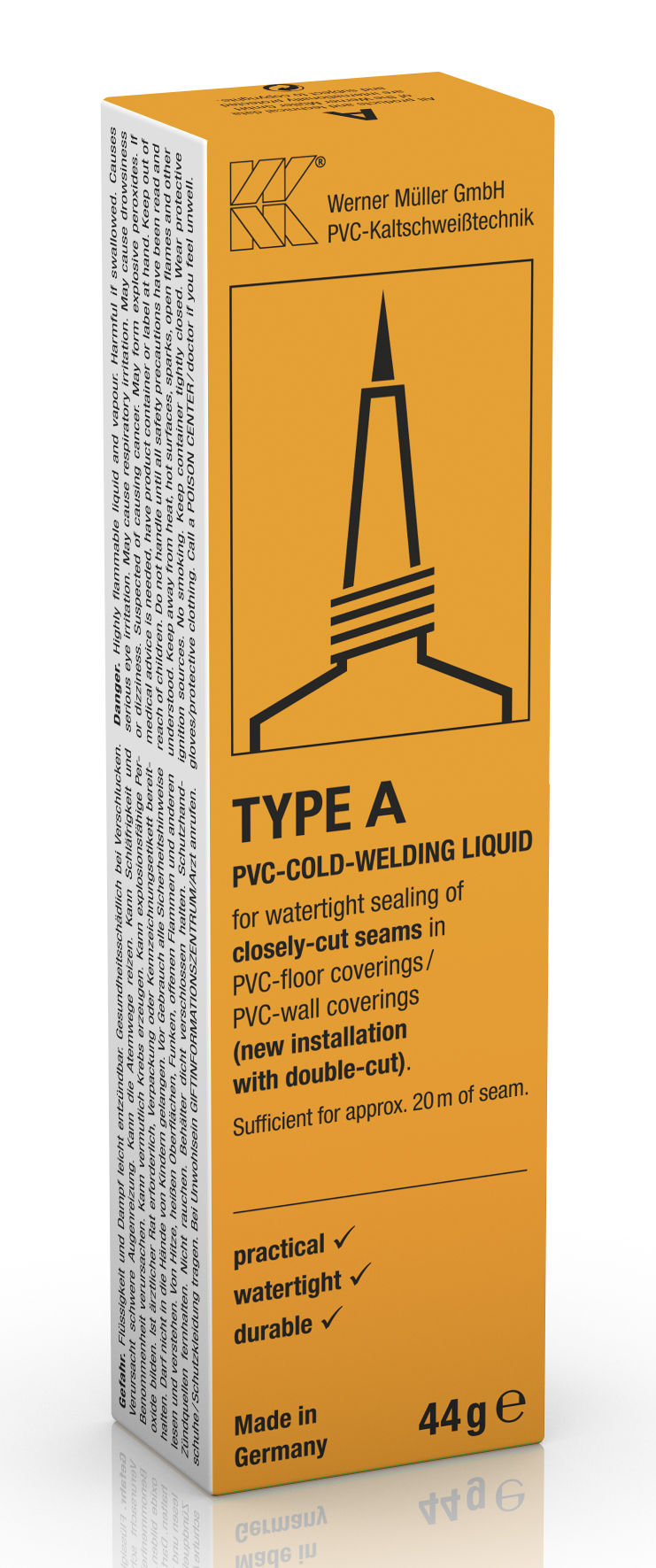

TYPE A

PVC-Cold-Welding Liquid

Field of application

Seam sealing of PVC-floor coverings / PVC-wall coverings

with closely-cut seam (new installation with double cut)

Characteristic

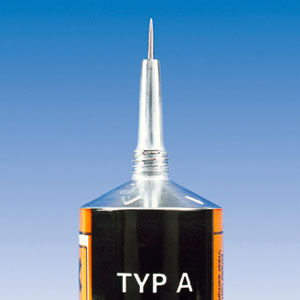

- Firmly mounted steel needle with special cap (closed system)

Properties

- very high seam tensile strength

- durable, waterproof seam sealing

- nearly invisible seams

- ready for use and reusable

Process

The steel needle penetrates deep into the seam area, opens it temporarily and

the cold-welding liquid flows along the needle into the seam. Thus adjacent

sheets will be temporarily dissolved and joined together strongly and permanently

in the whole cross section of the seam.

the cold-welding liquid flows along the needle into the seam. Thus adjacent

sheets will be temporarily dissolved and joined together strongly and permanently

in the whole cross section of the seam.

Durability

The durability lasts 3 years from the date of manufacturing, if the product is

always kept dry, free of frost and not stored above 30 °C.

always kept dry, free of frost and not stored above 30 °C.

Delivery programme

Available in sales boxes (displays) with tubes 44 g or 132 g.

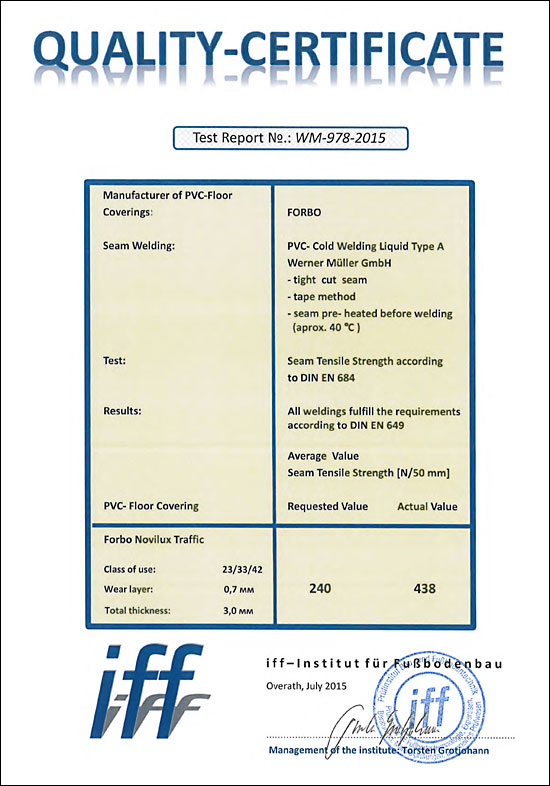

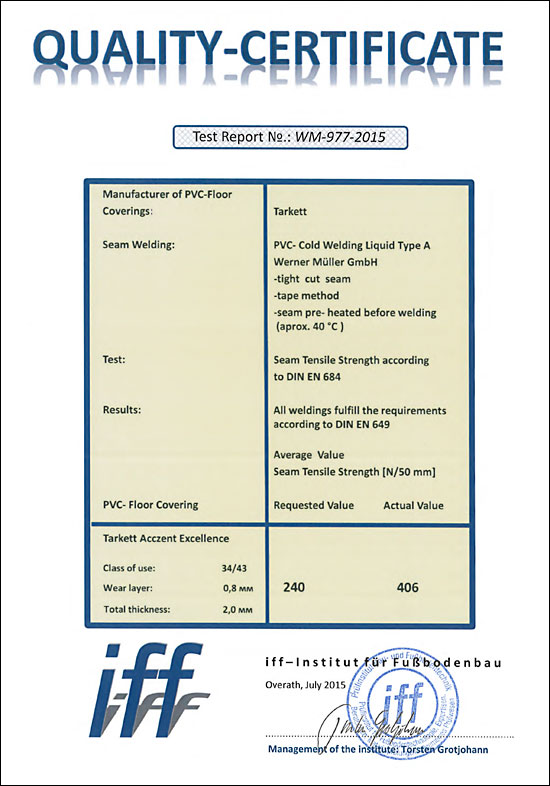

Seam Tensile Strength

Very high seam tensile strength –

exceeds the values of the European norm (DIN EN 649) by far.

Tested, validated and documented by the (independent German) iff-Prüfinstitut für Fußbodenbau (testing institute for the floor construction industry).

3 steps to a successful seam sealing exemplified by TYPE A

With just a few tools you achieve a lot!

Attach a special masking tape centred over the closely-cut seam and press on with a seam roll.

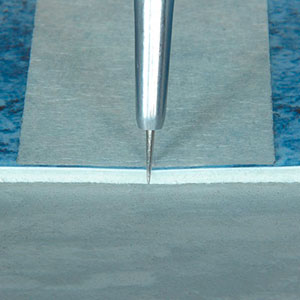

Cut the masking tape in the seam area with a rolling knife, a trapezoid blade or a hook blade. In case of stiff or little flexible PVC-floor coverings (for instance Commercial Floor Coverings) warm up the seam area to a maximum of 40 °C by using a blow dryer or an iron before welding.

Precautionary we recommend the use of safety gloves approved for Tetrahydrofuran for the prevention of skin contact (splash protection).

Always work with both hands!

Hold the tube in such a way that the index finger of one hand guides the cannula and the other hand holds the tube.

Press the needle deeply into the seam, go through the seam area steadily and control the rinse in a way to get an approximately 5 mm wide moistening on top of the masking tape.

Remove the masking tape about 10 minutes after the welding by pulling it steadily backwards at an angle.

The result:

A nearly invisible and waterproof seam!

Application video

PVC-Cold-Welding of RESIDENTIAL FLOOR COVERINGS

[lyte id='TKrESrrUAzk' /]

PVC-Cold-Welding of COMMERCIAL FLOOR COVERINGS

[lyte id='xZd6DB8lwiA' /]